Flexibility

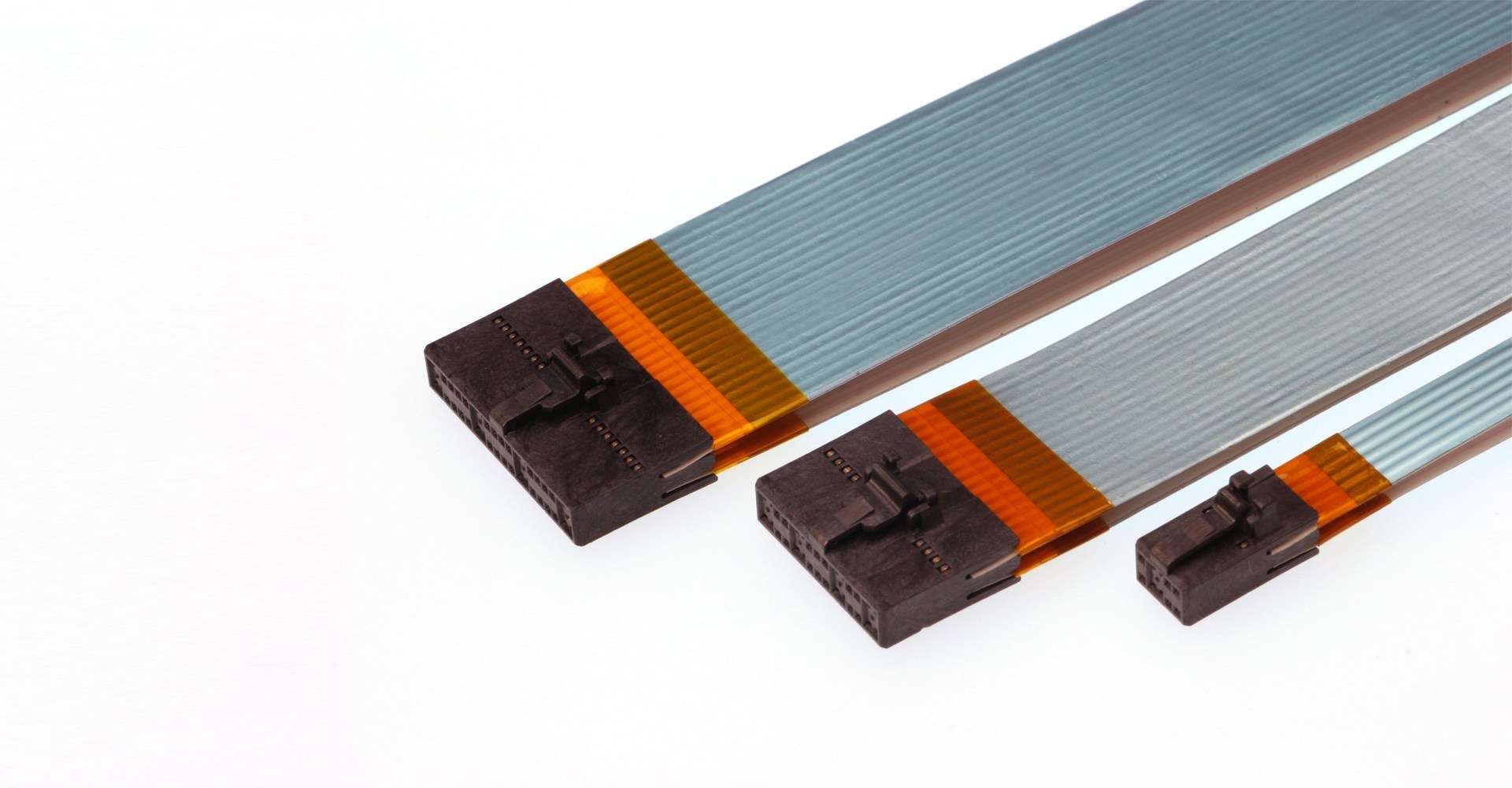

Flat flexible circuits are light weight, low profile, small outline cables designed to satisfy high density cabling applications.

Their distinguishing factors include repeated dynamic flexing and the ability to fold into nearly any shape, evenly distributing stress especially when compared to traditional cabling.

Any one of the following descriptions refers to flat flexible circuitry (FFC):

- Flat Flex Circuits

- Flat Flexible Cable

- Flat Flexible Conductor Cable

Flat flex circuits can be designed to hold any number of electrical components or simply as a connector between two circuits. Common industry applications include, but are not limited to:

- Consumer electronics

- Telecommunications

- Medical automotive

- Industrial

- Commercial

Advantages

There are several advantages that flexible printed circuits have over other interconnect devices:

- Signal Integrity – The material used in the construction of flex minimizes signal loss, maintaining high-speed integrity.

- Impedance Control – Flex promotes a robust design pitch due to the close proximity of circuitry and ground planes/shields.

- Temperature Resistant – Materials used in the construction of Flex have closely matching thermal expansion rates. This causes Flex to be suitable for hot and cold temperatures as well as large temperature fluctuations.

- Thermal Management – Flex does not require cooling from both sides. It also dissipates heat quickly.

- Space Reduction – Flex is able to occupy three dimensions. It can be bent around packaging and even over itself in order to fit into a much smaller device enclosure.

Weight Reduction – Flex is significantly thinner and lighter than traditional circuit boards; products using Flex will naturally be lighter.

As a unique flex circuit, the primary benefits of flat flex circuits include:

- High Flex Life

- Superior Heat Dissipation

- Light Weight

- Low Profile

- Durability

- Point-to-point Wire Replacement

- Foldable

- Multiple Termination Options

FPC – Flexible Printed Circuits

LOROM is your total solution for Flexible Printed Circuitry because we design and manufacture both the flex and the connectors. A Flexible Printed Circuit (FPC or Flex) is an ultra-reliable technology. An FPC can be the best solution for creating products, which are complex, small, and lightweight or have harsh environmental conditions. Flex can be designed to meet a wide range of temperature and environmental extremes.

This custom solution has a variety of applications. Flex circuits are excellent for designs with high-density circuitry and for dynamic applications such as hinge and drawer devices.

Flex circuits make electronic interconnection both simpler and more reliable. FPC interconnects are often used in applications where high signal speed, power distribution, heat, flexibility or space savings are issues. LOROM can provide your total interconnect solution.