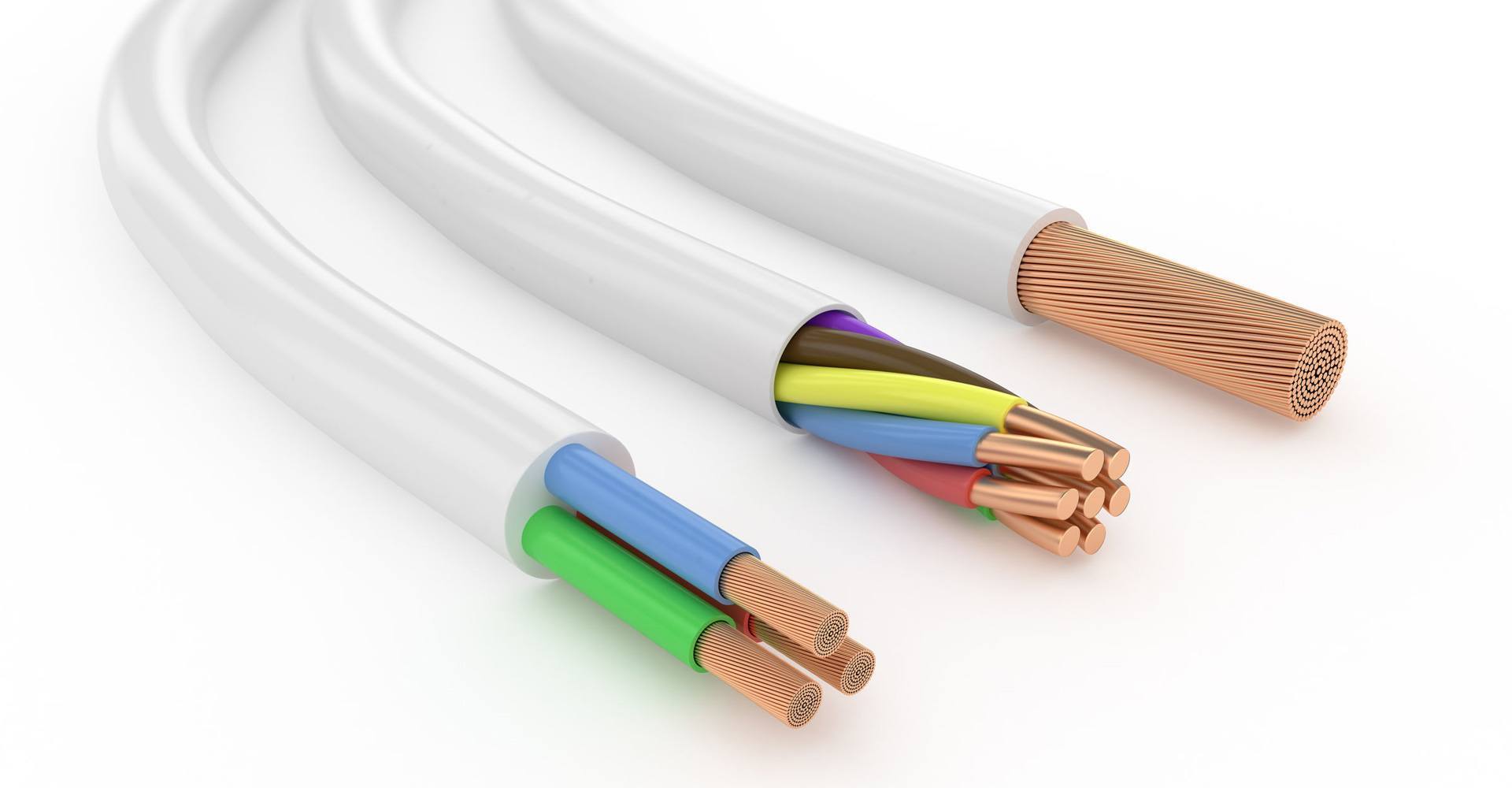

Bulk Cable Manufacturing

The LOROM Group specializes in the design and manufacture of standard and bespoke cables where the requirements are for innovation and high performance. Our unique in-house designed and manufactured cabling equipment allows us to develop unique products that give unsurpassed electrical and mechanical performance to meet our customer’s requirement.

Coupled with our vertical integration, conductor drawing, plating, and compound pelletizing it allows LOROM to tailor complete engineered solutions.

Specialists in Cable Innovation

Material Science

In-house compound development for PVC, PE, PP XLPE, Rubber, Silicone, PTFE, as well as proprietary customer application specific Thermoplastic Elastomers.

Insulation Materials

Specializing in the following wire insulation materials:

- PVC

- XLPE

- XLPVC

- HDPE

- FEP

- PFA

- Kapton

- PE

- Foam

- Silicone

- PTFE

- ETFE

- ePTFE

- Nylon

- Hytrel

- EPDM

- EPR

- Neoprene

- EVA

- PEEK

Thermoplastics and Thermoset Insulating and jacketing materials

LOROM Manufacturing Experience and Capabilities meets the needs and challenges of our Industry’s Requirements.

LOROM’s extensive experience with Thermoplastics and Thermoset insulating and jacketing material begins with the basic PVCs and polyolefins to highly specialized Fluoroplastics like FEP and TPE Thermoplastic Elastomers. Our manufacturing capability coupled with this knowledge makes LOROM the ideal choice for product designs that are capable of meeting the most demanding applications. In addition to this we can also foam these plastics to improve or lower signal loss and reduce weight and size.

Some examples of this are Plenum Cables, Industrial Cables and cables that are exposed to Hazardous Environments, High Temperatures and Chemicals.

Copper Conductor Offerings

From AWG50 – AWG000

LOROM’s specialty conductor & alloys:

- Cadmium Copper Alloy 162

- CS-95 (Beryllium Alloy)

- ‘Cadmium Free’ Alloy 135

- Tinsel Wire

- Thermocouple

- Litz Wire

Copper Plating Options

Tin: Good solderability and corrosion protection

Silver: Good solderability and high conductivity

Nickel: Corrosion protection and temperatures up to 250°

Enamel: Protection for ultra fine wire

Jacket Materials

Various jacket materials available:

- TPE

- TPE-V

- TPE-S

- TPE-A

- PEEK

- Silicone

- PTFE Tape

- EFTE

- PVC

- PE

- XLPE

- XLPVC

- Viton

- Hytrel

- EPDM

- EPR

- Neoprene

- EVA

- FEP

- PFA

- Kapton

- Nylon

- Hytrel

LOROM’s Unique Skin-Foam-Skin

LOROM’s Unique Skin-Foam-Skin Products provide Superior Performance

Let’s first start with the question why do we foam plastics? The obvious answer is to reduce weight and size. The most important benefit is to improve product performance. Foaming any product introduces air into the plastic structure and this reduces the weight but also lowers the dielectric constant of the material.