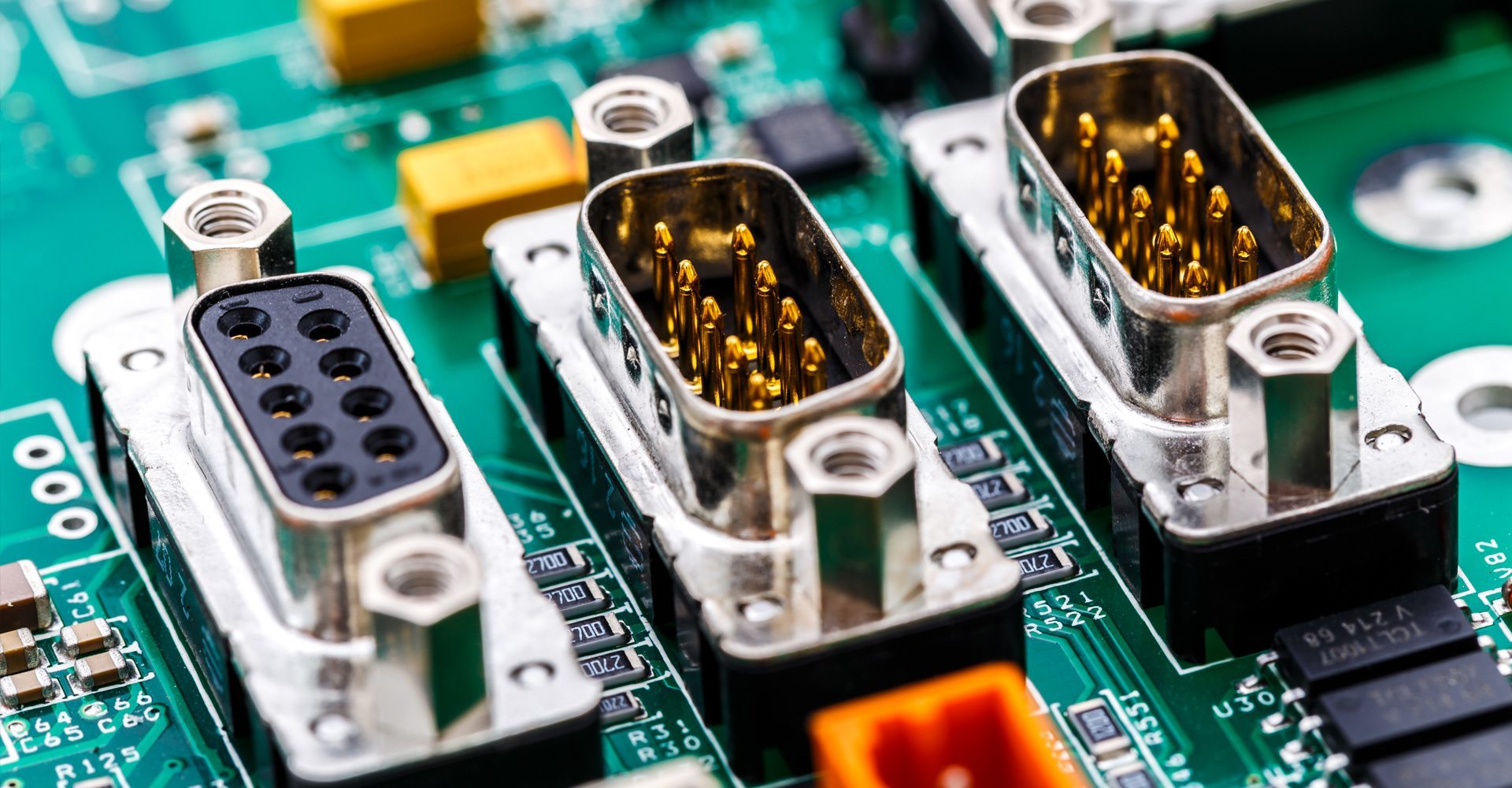

Excellence in Electronic PCB Assemblies

LOROM has invested significantly over the last 10 years in PCB assemblies to be able to offer our customer complete turnkey solutions and one stop shopping.

Combining design, manufacturing, product liability and life cycle testing to exceed our customer’s needs and expectations.

We have the latest sophisticated SMT equipment enabling unparalleled component placement accuracy.

Our assembly technology also includes press fit, wave solder and hand solder.

Our capabilities also include single sided, double sided (with or without PTH), multi-layer and flexi-rigid.

Technologies & Capabilities

- PCB design management, layout & prototyping

- Manual surface mount & PTH assembly for prototypes

- Fully automated surface mount and through hole PCB assemblies

- High accuracy BGA placement

- Automated PCB optical inspection

- X-Ray inspection and conformal coating

- Full in-house test capability

- Functionality testing

Testing

LOROM utilizes automatic optical inspection test solutions to include full in-circuit & functional test.

Delivering defect free assemblies through AOI, ICT and functional testing.

Capability

LOROM has extensive PCBA capability including surface mount, thru-hole and mixed technology that enables us to meet the most complex design and manufacturing requirements across a wide range of demanding applications and market sectors.

In addition to our surface mount capability, our continued investment brings a high level of automation to production ensuring best practice of manufacture, reduced cycle times and reliability in process and product conformity.

Surface Mount Technology

- 0201 Packages

- BGA/uBGA’s

- CSP’s

- LGA’s

- Forced Convection reflow

- Intrusive Reflow ( Paste in Hole)

- Leaded and/or Lead Free Process

Thru-Hole Assembly

- Automated Spade Insertion

- Flow Line Staged Insertion

- Press Fit Connectors

- Wave Soldering

- Selective soldering

- Leaded and/or Lead Free Process